Linear alcohol ethoxylates are a key class of non-ionic surfactants widely used across industrial, agricultural, and specialty chemical formulations. Known for their high efficiency, biodegradability, and formulation compatibility, they play a critical role in improving wetting, emulsification, dispersion, and cleaning performance across multiple industries.

As formulation requirements become more complex and sustainability standards continue to tighten, linear alcohol ethoxylates are increasingly preferred over branched alternatives. This guide explores what linear alcohol ethoxylates are, their structure, benefits, and how they are applied across various industrial sectors.

What Are Linear Alcohol Ethoxylates?

Linear alcohol ethoxylates are non-ionic surfactants produced by the ethoxylation of linear fatty alcohols with ethylene oxide. They belong to the broader family of alcohol ethoxylates and ethoxylated surfactants, differentiated by the straight-chain structure of their hydrophobic alcohol component.

Their linear molecular structure contributes to:

- Improved biodegradability

- Consistent performance across formulations

- Strong regulatory acceptance in global markets

Due to these characteristics, linear alcohol ethoxylates are widely used in applications where environmental performance, formulation stability, and efficiency are critical.

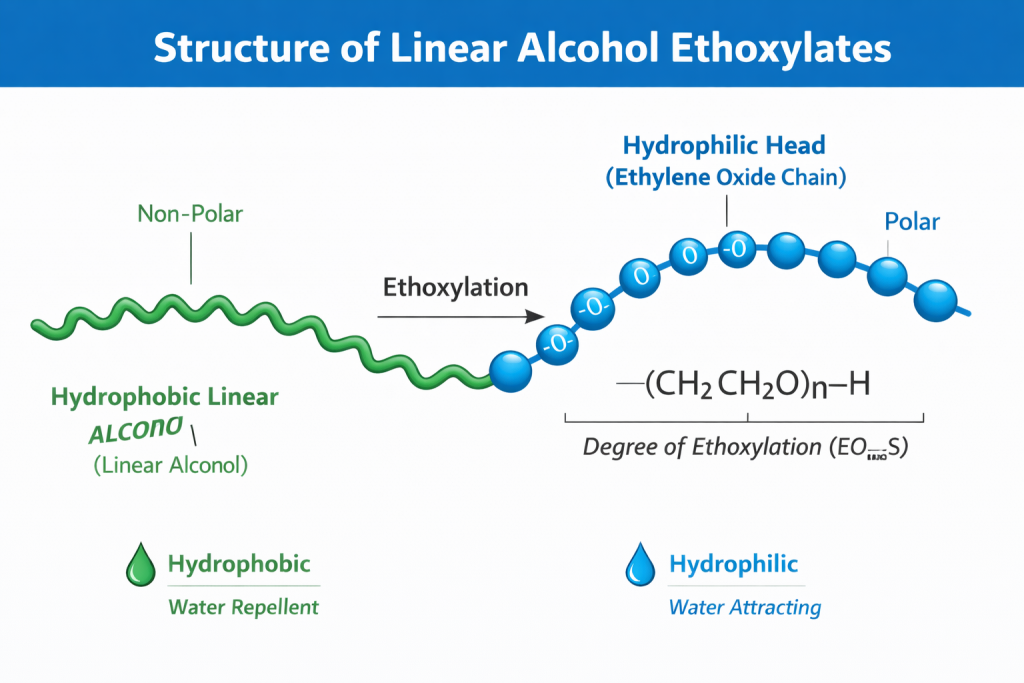

Structure of Linear Alcohol Ethoxylates

The structure of linear alcohol ethoxylates consists of two primary components:

- Hydrophobic linear alcohol chain: Derived from linear fatty alcohols (typically C₁₂–C₁₈), responsible for oil interaction and surface activity

- Hydrophilic ethylene oxide (EO) chain: A controllable number of EO units that provide water solubility and emulsifying power

The degree of ethoxylation directly influences key properties such as:

- Solubility in water and solvents

- Cloud point

- Wetting and detergency performance

- Emulsification strength

This tunable structure allows formulators to select linear alcohol ethoxylates tailored to specific industrial and formulation requirements.

Linear vs. Branched Alcohol Ethoxylates

While both linear and branched alcohol ethoxylates are effective non-ionic surfactants, linear variants are often preferred for their environmental and performance advantages.

Linear alcohol ethoxylates:

- Higher biodegradability

- Lower aquatic toxicity

- Better regulatory acceptance

- Consistent performance in agriculture and cleaning systems

Branched alcohol ethoxylates:

- Enhanced stability in extreme conditions

- Used in niche industrial applications

For industries prioritizing sustainability, regulatory compliance, and broad formulation compatibility, linear alcohol ethoxylates are typically the preferred choice.

Benefits of Linear Alcohol Ethoxylates

Linear alcohol ethoxylates offer a range of functional and operational advantages:

- Excellent wetting and spreading: Improves surface coverage and active ingredient distribution

- Strong emulsification: Stabilizes oil-water systems in complex formulations

- High compatibility: Performs well with acids, alkalis, salts, and other surfactants

- Non-ionic nature: Stable across varying pH levels and water hardness

- Improved biodegradability: Supports environmentally responsible formulations

These benefits make linear alcohol ethoxylates suitable for both high-performance industrial systems and environmentally sensitive applications.

Industrial Applications of Linear Alcohol Ethoxylates

Agriculture and Agrochemical Formulations

In agriculture, linear alcohol ethoxylates are widely used as:

- Wetting agents and spreaders

- Emulsifiers in EC, EW, ME, and SC formulations

- Adjuvants for foliar fertilizers and crop protection products

Their ability to improve spray coverage, penetration, and tank-mix stability enhances nutrient uptake and active ingredient efficiency while reducing chemical wastage.

Cosmetics and Personal Care

In cosmetic and personal care formulations, linear alcohol ethoxylates function as:

- Emulsifiers

- Cleansing agents

- Solubilizers

They are commonly used in creams, lotions, cleansers, and shampoos due to their mildness, stability, and compatibility with other formulation ingredients.

Industrial Cleaning and Detergents

Linear alcohol ethoxylates are a cornerstone of industrial and institutional cleaning products. Their high detergency and low foaming options make them suitable for:

- Hard surface cleaners

- Degreasers

- Industrial washing formulations

Their effectiveness in both soft and hard water conditions ensures consistent cleaning performance.

Paints, Coatings, and Polymeric Emulsions

In paints, coatings, and polymer emulsions, linear alcohol ethoxylates are used as:

- Wetting agents

- Emulsion stabilizers

- Dispersants

They help improve pigment dispersion, emulsion stability, and overall formulation consistency, contributing to improved application and film performance.

Pharmaceuticals and Specialty Formulations

Linear alcohol ethoxylates are also used as formulation aids and excipients in pharmaceutical and specialty chemical systems. They support:

- Improved solubility of active ingredients

- Enhanced formulation stability

- Controlled dispersion in liquid systems

Selection of appropriate grades is essential to meet regulatory and purity requirements.

Regulatory and Environmental Considerations

Linear alcohol ethoxylates are generally recognized for their favorable environmental profile compared to other surfactant classes. Their linear structure supports higher biodegradability and lower persistence in the environment.

They are widely accepted under major regulatory frameworks, provided they are used in compliance with recommended application guidelines and industry standards.

Choosing the Right Linear Alcohol Ethoxylate Supplier

Selecting a reliable linear alcohol ethoxylate supplier is critical to ensuring consistent product quality, technical support, and regulatory compliance. Key factors to consider include:

- Availability of multiple EO grades

- Technical documentation (MSDS, TDS, COA)

- Industry-specific expertise

- Flexible global logistics and supply options

Linear Alcohol Ethoxylates at SBR International

At SBR International, we supply high-quality linear alcohol ethoxylates tailored for agriculture, personal care, industrial cleaning, coatings, pharmaceuticals, and performance chemical applications. Our portfolio is supported by strong technical expertise, regulatory documentation, and global logistics capabilities, including FOB, CFR, and CIF delivery options.

With a focus on formulation-driven solutions and long-term partnerships, SBR International works closely with customers to ensure consistent performance, regulatory compliance, and reliable supply across global markets.