Selecting the right surfactant system is one of the most critical decisions in formulation science. Whether developing agrochemicals, cosmetics, pharmaceuticals, or industrial emulsions, formulators rely on the HLB system to predict how surfactants behave in oil–water systems and to design stable, high-performing products.

The HLB system provides a practical framework for emulsifier selection, guiding formulators in choosing individual surfactants or creating optimized surfactant blends. This article explains the HLB system in detail, how it is used in real formulations, and why it remains a foundational tool across industries.

What Is the HLB System?

The HLB system, or Hydrophilic–Lipophilic Balance system, is a numerical scale that describes the balance between the water-attracting (hydrophilic) and oil-attracting (lipophilic) portions of a surfactant molecule.

In simple terms, the HLB value indicates:

- How soluble a surfactant is in water

- Whether it will favor oil-in-water or water-in-oil emulsions

The HLB system helps formulators predict surfactant behavior without relying solely on trial and error.

HLB System Full Form and Origin

HLB system full form: Hydrophilic–Lipophilic Balance

The concept was introduced to simplify emulsifier selection by assigning numerical values to surfactants based on their molecular structure. While originally developed for non-ionic surfactants, the HLB system is now widely applied across multiple formulation technologies.

How the HLB System Works

Each surfactant is assigned an HLB value based on the relative contribution of its hydrophilic and lipophilic components.

- Low HLB values indicate oil-soluble surfactants

- High HLB values indicate water-soluble surfactants

By matching the HLB value of a surfactant (or surfactant blend) to the requirements of the oil phase, formulators can achieve stable emulsions and predictable performance.

HLB System Ranges and Their Meaning

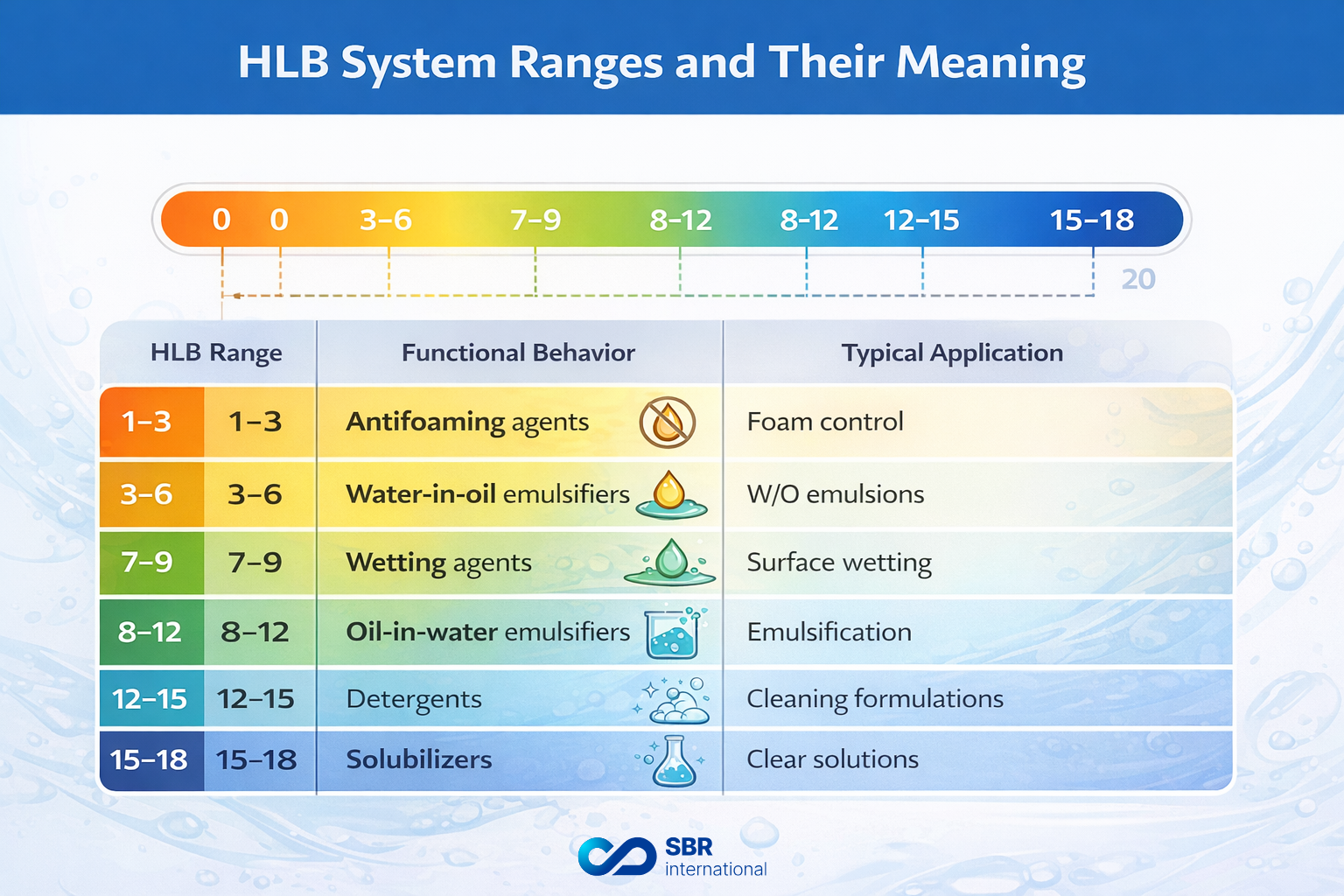

The HLB system typically ranges from 0 to 20, with each range corresponding to a functional role:

HLB Range | Functional Behavior | Typical Application |

1–3 | Antifoaming agents | Foam control |

3–6 | Water-in-oil emulsifiers | W/O emulsions |

7–9 | Wetting agents | Surface wetting |

8–12 | Oil-in-water emulsifiers | Emulsification |

12–15 | Detergents | Cleaning formulations |

15–18 | Solubilizers | Clear solutions |

Why Surfactant Blends Are Often Preferred

In practical formulation work, a single surfactant rarely delivers all the performance characteristics required for a stable and efficient product. Different surfactants contribute different functional strengths—such as emulsification power, wetting ability, stability across temperatures, or tolerance to electrolytes.

By using surfactant blends, formulators can combine the strengths of multiple surfactants to achieve a more balanced and robust system. Blending allows precise control over the final HLB value while also improving emulsion stability, reducing sensitivity to formulation variables, and enhancing long-term storage performance.

Surfactant blends are often preferred because they:

- Provide better emulsion stability across temperature variations

- Improve resistance to phase separation and creaming

- Allow fine-tuning of performance without changing the oil phase

- Offer cost and performance optimization

As a result, surfactant blends are widely used in agrochemicals, cosmetics, pharmaceuticals, and industrial emulsions where formulation reliability is critical.

How Formulators Calculate HLB for Surfactant Blends

The HLB of a surfactant blend is calculated as a weighted average of the individual surfactants:

HLB (blend) = (HLB₁ × wt%) + (HLB₂ × wt%)

This approach allows formulators to design emulsifier systems that exactly match the required HLB of the oil phase, improving formulation robustness.

Emulsifier Selection Using the HLB System

The HLB system serves as a practical decision-making tool for emulsifier selection, especially in oil–water systems. Rather than testing surfactants randomly, formulators use the HLB concept to narrow down suitable options early in the development process.

The typical emulsifier selection process using the HLB system involves:

- Identifying the oil phase and its required HLB value

- Selecting surfactants within the appropriate HLB range

- Blending surfactants to match the target HLB

- Validating emulsion stability through laboratory testing

This approach improves formulation efficiency and reduces development time. While the HLB system does not replace experimental testing, it provides a strong starting framework that increases the likelihood of achieving stable emulsions with fewer reformulation cycles.

HLB System Applications Across Industries

Agrochemical Formulations

The HLB system is widely used to select surfactants for EC, EW, and SC formulations. Correct HLB selection ensures stable emulsions, effective dispersion, and reliable field performance.

Cosmetics and Personal Care

HLB values guide emulsifier selection for creams, lotions, and cleansers, influencing texture, stability, and sensory properties.

Pharmaceuticals

In pharmaceutical formulations, the HLB system supports emulsifier and solubilizer selection to improve active ingredient delivery and stability.

Industrial and Performance Chemicals

The HLB system is applied in detergents, coatings, polymer emulsions, and cleaning products to achieve predictable performance.

Limitations of the HLB System

Although the HLB system is widely used, it is important to understand its limitations. The system primarily focuses on the balance between hydrophilic and lipophilic components and does not account for all formulation variables.

Key limitations include:

- It does not consider temperature sensitivity or cloud point behavior

- It does not predict electrolyte or pH interactions

- It does not address rheology, viscosity, or shear stability

- It is most applicable to non-ionic surfactants

Because of these limitations, the HLB system should be viewed as a guiding framework, not a standalone solution. Successful formulations combine HLB-based selection with formulation testing, stability studies, and performance validation under real-use conditions.

Choosing the Right Surfactant Solutions with SBR International

At SBR International, we support formulators with a wide range of surfactants and emulsifier systems designed for precise HLB control. Our expertise in surfactant blends, technical documentation, and formulation support helps customers develop stable, efficient products across agriculture, personal care, and industrial applications.

With global sourcing capabilities and flexible logistics options, SBR International partners with customers to translate formulation theory into reliable commercial performance.

Work with SBR International for Optimized Surfactant Solutions

At SBR International, we help formulators translate HLB theory into practical, high-performing surfactant systems. Our portfolio includes a wide range of non-ionic surfactants and emulsifier solutions designed for precise HLB control across agrochemical, personal care, pharmaceutical, and industrial applications.

With strong technical expertise, detailed product documentation (MSDS, TDS, COA), and global logistics capabilities, SBR International supports customers from formulation development through commercial scale-up.

If you are developing or optimizing formulations and need support with surfactant selection or surfactant blends, our team is available to assist with tailored technical guidance.

Contact SBR International to discuss your formulation requirements and explore customized surfactant solutions.